Building formwork is a temporary support structure made according to design requirements, which enables concrete structures and components to form in the specified position and geometric dimensions, maintain their correct position. Our products have different levels of nail holding ability and can be adjusted on demand.

UMeta provides wholesale and recycle services for Building formwork. You can contact us via Email or Livechat.

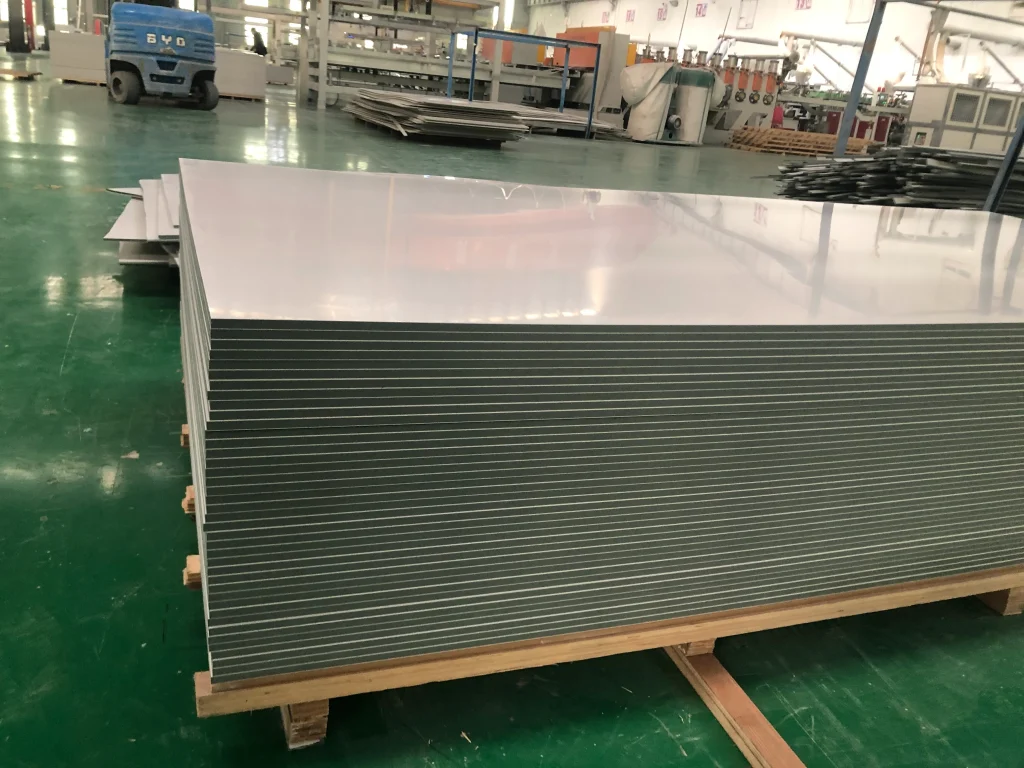

- Product Picture

- Basic Info

- Advantages

- Packaging&Delivery

| Model NO. | PVC Formwork | Material | PVC |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Gloss | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Construction Concrete |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

| Surface nail-holding | ≥1100N | Foam nail-holding | ≥750N |

Products can be customized on demand.

- Smooth and flat. The template splicing is tight and smooth, and the surface and flatness of the concrete structure after demolding exceed the technical requirements of the existing clear water template, without the need for secondary plastering, saving labor and materials.

- Lightweight and easy to install. Lightweight and highly adaptable to manufacturing processes. It can be sawed, planed, drilled, nailed, and shaped into any geometric shape to meet the needs of various shapes of building templates.

- Easy demolding. Concrete does not stick to the surface of the board, does not require release agents, and is easy to demold and remove dust.

- Stable and weather resistant. High mechanical strength, no shrinkage, expansion, cracking, deformation, dimensional stability, alkali resistance, corrosion resistance, flame retardant, waterproof, rodent proof, insect proof under temperature conditions of -20 ° C to+60 ° C.

- Beneficial for maintenance. The template does not absorb water and does not require special care or storage.

- Strong variability. The type, shape, and specifications can be made according to the requirements of the construction project.

- Reduce costs. Large turnover times, no less than 30 times for flat molds and no less than 40 times for column and beam molds, with low operating costs.

- Energy conservation and environmental protection. All scraps and used templates can be recycled with zero waste discharge.

| Package Size | 580.00cm * 320.00cm * 250.00cm |

| Package Gross Weight | 1850.000kg |