hello

this is a test

hello

this is a test

SPC Wall Panel is a revolutionary new environmentally friendly building decoration material made of Stone Plastic Composite. The full name is “Stone Plastic Composite Wall Panel” or simply “Stone Plastic Composite Wall Board”. ), it is a “cross-border new material” that replaces slate, ceramic tiles, ice and fire boards, wood veneers, and anti-bacterial materials.

UMeta provides wholesale services for SPC Wall Panel. You can contact us via Email or Livechat.

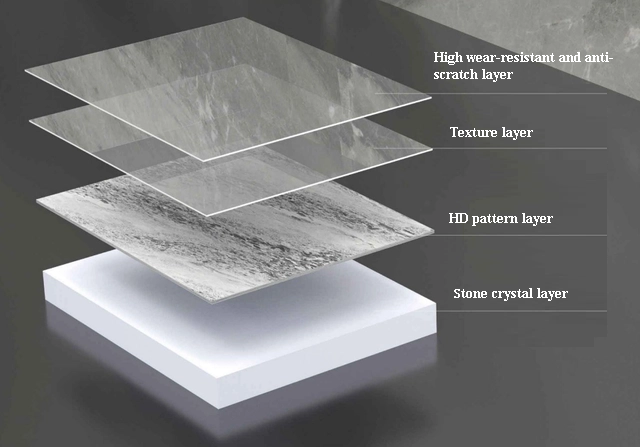

SPC stone crystal wall panels also have good natural texture, and their surface texture simulates the texture of natural materials, giving people a natural touch. The surface pattern adopts ultra-clear digital printing or decorative film or color film. The surface of the product has a mirror high gloss or soft skin texture or textures such as wood grain, stone grain, leather grain, cloth grain, metal grain and terrazzo, thus forming a stone crystal wall panel.

◆ The surface wear resistance is high, has the higher flame retardant performance, the anti-pollution corrosion ability is strong, the anti-pressure, the anti-impact performance is good

◆ Easy to clean and care

◆ Dimensional stability is good, because this can assure, the aperture between the floor in using a process is lesser, not easy arch

◆ Easy to lay

◆ Ultra-light, ultra-thin, fireproof, waterproof, moisture-proof, sound-absorbing, noise-proof and antibacterial properties.

◆ Acid and alkali corrosion resistance

◆ Anti-static and anti-skid

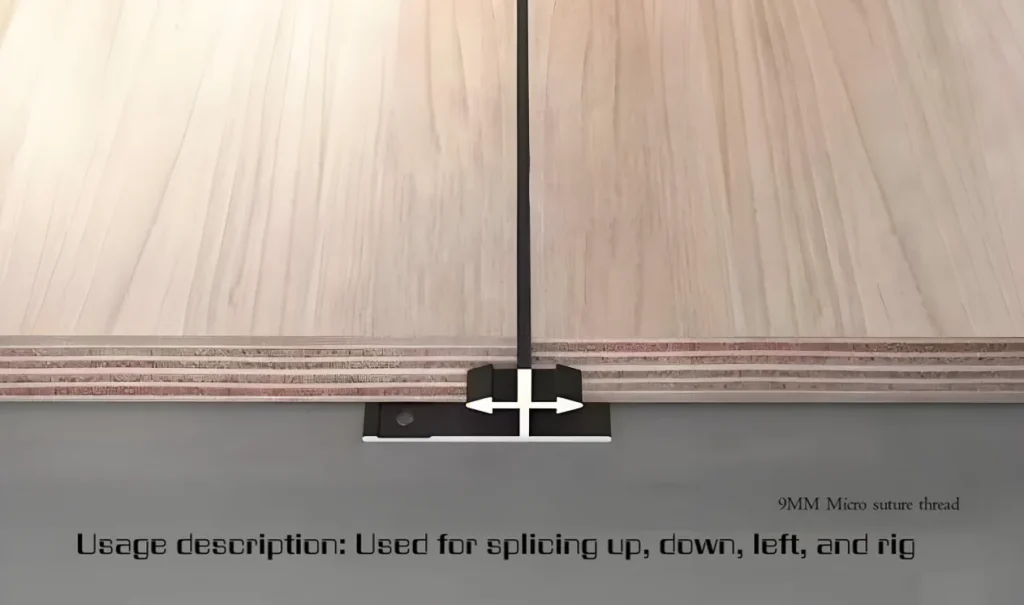

◆ Easy to cut and splice, reduce waste and can be installed quickly

| Model NO. | SPC Flooring/SPC Floor | Material | PVC,Calcium Carbonate |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Matt/ Parquet | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Household, Outdoor, Commercial |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

Products can be customized on demand.

SPC wall panels are heated and bonded, completely eliminating glue. No harmful gases are produced during the entire production process, achieving zero formaldehyde addition, and are harmless to the human body. It is a green and environmentally friendly decoration material. , ensuring green environmental protection.

SPC wall panels are mainly composed of stone powder and polymer resin. With their high content of calcium carbonate, they show good flame retardant and fire retardant properties, which can effectively retard and reduce fire risks. Even in the face of high temperature tests, it can maintain its stable shape without discoloration or deformation, building a solid line of defense for residential safety. For this reason, SPC wall panels can be widely used in interior decoration, especially in places with high fire risks such as public places and high-rise buildings.

Stone crystal wall panels have excellent moisture-proof and mildew-proof properties, can effectively resist humid environments, and are not easy to breed mold; and are specially designed to prevent swelling and blistering even if soaked for a long time, effectively preventing water seepage that may cause solve the problem of wall damage and make the decoration effect more lasting. Therefore, it can be used in relatively humid spaces, such as bathrooms, kitchens, balconies and other spaces.

SPC wall panels adopt a dry-hanging installation method, which is easy to construct, ready to install and use, and has a short cycle. It can improve the decoration efficiency and is suitable for the quick installation needs of hotels, restaurant chains, commercial offices and other spaces.

The surface of the stone crystal wall panel is hard and smooth, and it is not easy to absorb dust. It is easy to clean and maintain. It can be cleaned with a gentle wipe with a rag, which can keep the wall clean for a long time.

Its high-density, high-fiber mesh structure base layer gives the wallboard strong hardness and toughness, which can remain intact even in the face of unexpected impacts; the super wear-resistant polymer covered on the surface is wear-resistant The layer gives it excellent scratch resistance, keeping the surface as smooth as new even with frequent use or accidental scratches.

SPC wall panels also have good sound absorption effects, which can effectively reduce indoor noise and improve the comfort of the living environment.

SPC wall panel installation does not require glue, etc. You only need to use tools to cut and snap them together in the correct order to form a floating floor.

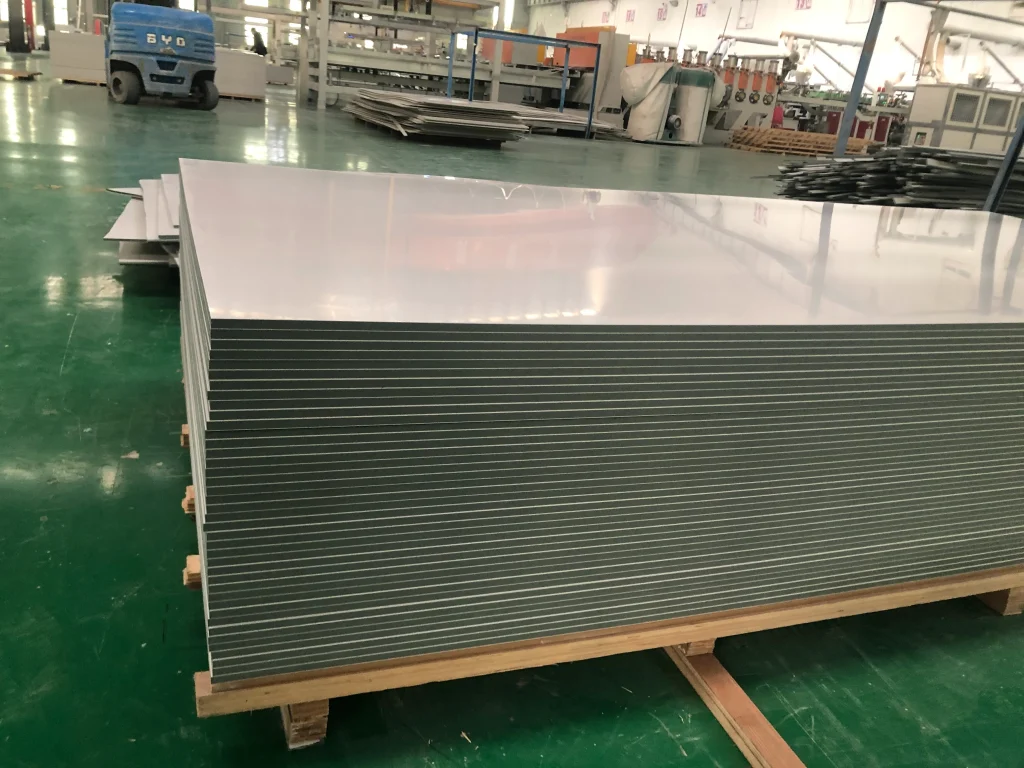

Package as shown in the following figure.

Just sweep or mop regularly.

Wear slippers at home and clean them promptly to avoid damage.

UMeta’s SPC wall panel ensures environmental protection and is non-toxic and will not release formaldehyde or any toxic substances. It is an excellent choice for families with children or pets.

UMeta provides wholesale services for SPC Flooring. You can contact us via Email orLivechat.

Chevy board, also known as PVC foam board or Andy board, is a kind of board extruded by special equipment with polyvinyl chloride (PVC) as the main raw material, added with foaming agent, flame retardant and anti-aging agent. Common colors include white and black.

UMeta provides wholesale services for Chevy board. You can contact us via Email or Livechat.

It can be used for architectural decoration, furniture production, shipbuilding, etc.

It is also used for packaging, printing, cultural and artistic purposes.

Due to its excellent processing performance and environmental characteristics, Xuefu board is often used in advertising production, exhibition signage, urban environmental protection and other fields.

| Model NO. | PVC FOAM BOARD | Material | PVC |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Matt/ Glos | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Household, Outdoor, Commercial |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

Products can be customized on demand.

Due to its special foam structure, the Chevrolet board is not easily deformed or cracked during use.

It can be processed through various methods such as sawing, planing, nailing, and sticking, and is suitable for various application scenarios.

Snowboard usually does not contain formaldehyde, but it is necessary to choose products produced by regular manufacturers to avoid formaldehyde pollution.

| Package Size | 570.00cm * 230.00cm * 245.00cm |

| Package Gross Weight | 1900.000kg |

Carbon crystal board, whose scientific name is “bamboo charcoal co-extruded decorative panel”, also known as “bamboo carbon board”, is a wood-plastic board made by high-temperature extrusion process. Its core raw materials include bamboo charcoal powder, calcium powder, PVC and additives.

UMeta provides wholesale services for Carbon Crystal Board. You can contact us via Email or Livechat.

The structure of the carbon crystal plate is complex and delicate, from top to bottom:

1. High strength and light weight: Carbon fiber is a material with extremely high strength, which makes the carbon crystal plate have good load-bearing capacity. At the same time, it is light and easy to install and carry.

2. Good thermal conductivity: The carbon crystal plate has fast thermal conductivity and can transfer heat evenly in a short time. It is suitable for use in floor heating, wall heating and other occasions that require rapid heating.

3. Corrosion resistance and aging resistance: Carbon crystal plates have good resistance to most chemical substances, and have stable performance and long service life under long-term use.

4. Products can be customized on demand.

Because of its unique properties, carbon crystal panels have wide application prospects in whole house decoration.

1. Wall material: Carbon crystal board can be used as a lightweight partition board, which not only can effectively reduce the burden of the building, but also has good thermal insulation performance.

2. Floor material: The carbon crystal plate used for the floor can not only withstand large loads, but also transfer heat quickly, making it an ideal choice for floor heating systems.

3. Ceiling material: Carbon crystal plate has good sound insulation effect and can be used as ceiling material to create a quiet and comfortable indoor environment.

4. Furniture materials: The characteristics of light weight and high strength make carbon crystal panels an ideal material for making furniture, which is both beautiful and durable.

Carbon crystal panels can be used as an ideal choice for whole-house decoration and are used in walls, floors, ceilings and furniture materials. They have the advantages of environmental protection and energy saving, convenient construction, comfort and health, and flexible design. However, the cost of carbon crystal panels is high, installation requires professional skills, limited designability, difficulty in repair and insufficient market awareness.

1. Advantages

• High strength and lightness: Carbon crystal plates have extremely high strength and lightness due to their carbon fiber composition. This means that home products and structures can be constructed to withstand greater stresses and impacts while reducing the weight of the building.

• Corrosion resistance: Carbon crystal plate has good high temperature resistance, corrosion resistance, wear resistance and other properties. It has good corrosion resistance to a variety of chemical substances. It is suitable for a variety of environments, has a long service life, and is not easy to deform. cracking, reducing the need for routine maintenance.

• Good thermal conductivity: Its excellent thermal conductivity means it can be effectively used in situations where rapid heat dissipation is required. It can also be used as a material in heating systems such as floor heating to improve energy efficiency.

• Good toughness and stability: The added polymer allows the carbon crystal plate to maintain dimensional stability and not easily deformed even under temperature changes or physical impact.

• Environmental protection and energy saving: Carbon crystal panels do not release harmful gases during production and use. They cause little pollution, are harmless to the human body, effectively reduce energy consumption, are in line with the current green environmental protection trend, and are a green and environmentally friendly building material. Reducing reliance on traditional building materials can help reduce environmental damage and increase energy efficiency.

• Easy to install: The carbon crystal plate is light in weight, small in size and easy to process. It is easy and fast to install and does not require complicated construction techniques. It greatly simplifies the construction process, shortens the construction period, and reduces installation costs and time.

• Easy to clean: The smooth surface of the carbon crystal plate makes it less likely to be contaminated with dust and dirt, making it easy to clean and maintain, making the environment more glamorous.

• Decoration effect and style diversity: The carbon crystal plate has a smooth surface and bright colors. It can imitate various textures and materials. It can be customized in various sizes and shapes according to needs, and the decoration style can also be selected according to personal preferences, providing more opportunities for interior decoration. Multiple design freedoms to enhance the quality of your home or building

2. Disadvantages

• Higher cost: Compared with traditional construction and decoration materials, the production cost of carbon crystal panels is higher, so its market price is also relatively high, and the initial investment is large, which may increase decoration or construction costs.

• Installation expertise: Because it is a new type of material, it requires professional technology and workers for installation and maintenance, which may limit its application in some areas. Although it is easy to install, it has high requirements on the installation environment and installation technology. If it is installed improperly, its use effect may be affected.

• Limited designability: Although it has many advantages, it may not be as flexible as traditional materials in some design aspects, especially in terms of color and texture choices.

• Difficulty of repair: Due to the high integration and stability of carbon crystal plates, once carbon crystal plates fail or are damaged, they may be more difficult to repair than traditional materials, especially in complex or delicate structures. Repairs are difficult and may require professional work.

• Market awareness: As a new material, carbon crystal panels may not be sufficiently recognized and accepted in the market, and consumers may not have a deep understanding of its performance, uses, etc., which may affect its use in residential and residential applications. Application in commercial projects.

Bamboo Charcoal Board is a board made of bamboo charcoal as the main raw material and processed through various processing techniques. Bamboo charcoal refers to an environmentally friendly material made by carbonizing, drying and crushing fresh bamboo at high temperatures.

UMeta provides wholesale services for Bamboo Charcoal Board. You can contact us via Email or Livechat.

◆ Bamboo charcoal boards can be used for TV background walls, furniture partitions, and various cabinets (such as wardrobes, partition cabinets, high and low cabinets, shoe cabinets, sideboard cabinets, bar cabinets, etc.)

◆ Environmental protection, flame retardant, waterproof, moisture-proof, heat insulation, sound insulation, corrosion resistance, easy to clean and other features make it an ideal choice for home decoration, especially in humid environments.

| Model NO. | Bamboo Charcoal Board | Material | bamboo charcoal powder |

| Thickness | 2-10mm | Width | 600/v seam |

| Surface Treatment | Matt/ Parquet | Function | Dimensional stability, Excellent adsorption, Insect-proof and mildew-proof, Environmental protection, etc. |

| Color | Multi-Color | Usage | Household, Commercial |

| Transport Package | Wooden crate | Weight | 16.3KG/m² |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220*2440mm, 1500*3000mm, etc. |

| Thickness | 0.9cm | Production Capacity | 500000pieces /Year |

Products can be customized on demand.

1.Dimensional Stability

It is a hollow structure with good dimensional stability. The materials are installed in a prefabricated manner during the decoration and construction process, which shortens the decoration and construction period;

2.Excellent Adsorption

Bamboo Charcoal Board is made of bamboo that has been carbonized at high temperature. It has very good adsorption properties and has functions such as sterilization, deodorization, and humidity adjustment. It can absorb and remove odors and impurities in the air, keep the air fresh, and can be used for home decoration. The environment plays a very good role in improving it. The highly developed pore structure and bamboo charcoal molecules with strong adsorption capacity can naturally capture formaldehyde and other harmful substances in the air.

3. Insect-Proof and Mildew-proof

The natural pore structure of bamboo charcoal can absorb moisture in the air, adjust the dry humidity in the room, and has special effects of preventing mildew, moisture, and insects.

4. Corrosion Resistance

Good environmental protection and corrosion resistance, high stability and durability, etc. Bamboo carbon boards undergo a carbonization process to achieve anti-corrosion, insect-proof, and waterproof effects, and can effectively extend the service life.

5. Environmental Protection Performance

Bamboo carbon board is a new environmentally friendly material. It is made from bamboo straw, corn cob hemp stalk and other plant materials through rolling, drying, carbonization and other processes. It does not contain any pollutants and is a A truly environmentally friendly material.

6. Flame Retardant

Bamboo charcoal board has good flame retardant performance (B1 level), which provides guarantee for home safety.

7. Health Care

Release negative ions to make indoor air fresh and pleasant, while eliminating fatigue, promoting sleep, enhancing appetite, and promoting blood circulation.

8. Strong Decorative Properties

The surface of bamboo charcoal board is rich in colors and can meet the needs of different decoration styles.

9. Convenient Installation

Clamp plate structure and modular installation make the installation process more convenient and the construction period shorter.

10. Easy to Clean

Bamboo charcoal board has strong stain resistance and wear resistance, and is suitable for use in various occasions that require frequent cleaning and friction.

◆ Ultra-light, ultra-thin, fireproof, waterproof, moisture-proof, sound-absorbing, noise-proof and antibacterial properties.

◆ Acid and alkali corrosion resistance

◆ Anti-static and anti-skid

◆ Easy to cut and splice, reduce waste and can be installed quickly

Seashell Board is a new type of decorative material made from shells. It is composed of seashell powder and polymer materials. It can be used for indoor wall decoration with rich colors and high lifelikeness. Seashell Board has the characteristics of natural beauty, environmental sustainability and excellent performance.

UMeta provides wholesale services for SeaShell Board. You can contact us via Email or Livechat.

Products can be customized on demand.

This is a high-end ceramic tile product that combines sea shells and ceramic tiles and is made using a special process. The ceramic tile surface has a shiny sea shell texture and has excellent decorative effects.

Seashell Board flooring uses a similar production process to combine seashells with floor materials, so that the floor surface presents a natural seashell texture, improving the decoration and personalization of the floor.

Seashell wall panels are made of seashell flakes and polymer materials. They can be used for indoor wall decoration. They have unique shell texture and rich luster.

Seashell Boards can also be used to make various decorative accessories, such as vases, mirror frames, etc. These accessories have a shining shell texture, which can increase the artistic and romantic atmosphere of the indoor space.

In addition, Seashell Boards can be used to make decorative paintings, and the shells are collaged on the canvas to bring a natural and fresh feeling to the indoor space.

The above are just some common types of Seashell Board decorative materials. With the development and innovation of technology, more styles and types of Seashell Board products will appear.

Building formwork is a temporary support structure made according to design requirements, which enables concrete structures and components to form in the specified position and geometric dimensions, maintain their correct position. Our products have different levels of nail holding ability and can be adjusted on demand.

UMeta provides wholesale and recycle services for Building formwork. You can contact us via Email or Livechat.

| Model NO. | PVC Formwork | Material | PVC |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Gloss | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Construction Concrete |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

| Surface nail-holding | ≥1100N | Foam nail-holding | ≥750N |

Products can be customized on demand.

| Package Size | 580.00cm * 320.00cm * 250.00cm |

| Package Gross Weight | 1850.000kg |

SPC(Stone Plastic Composite) flooring/floor is a luxury acetylene-based flooring or tile flooring with a stone plastic composite or stone polymer composite core. It is an alternative to WPC flooring.

UMeta provides wholesale services for SPC Flooring. You can contact us via Email or Livechat.

◆ The surface wear resistance is high, has the higher flame retardant performance, the anti-pollution corrosion ability is strong, the anti-pressure, the anti-impact performance is good

◆ Easy to clean and care

◆ Dimensional stability is good, because this can assure, the aperture between the floor in using a process is lesser, not easy arch

◆ Easy to lay

Shopping malls, Office buildings, etc.

◆ Ultra-light, ultra-thin, fireproof, waterproof, moisture-proof, sound-absorbing, noise-proof and antibacterial properties.

◆ Acid and alkali corrosion resistance

◆ Anti-static and anti-skid

◆ Easy to cut and splice, reduce waste and can be installed quickly

| Model NO. | SPC Flooring/SPC Floor | Material | PVC,Calcium Carbonate |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Matt/ Parquet | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Household, Outdoor, Commercial |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

Products can be customized on demand.

SPC flooring is resistant to wear, impact, scratches, and dents due to its manufacturing materials and multi-layer construction. It can handle dropped items and pet bites when used in the home, and can handle heavy foot traffic when used in corridors, entryways, etc. It can well maintain its original appearance without much wear and tear. In addition, its exterior coating resists wear and tear caused by direct sunlight. SPC flooring has a long service life, usually 20-30 years.

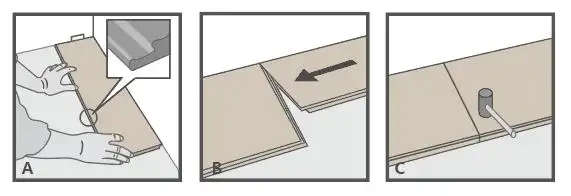

SPC flooring floats above the subfloor, so there is no need to remove the original flooring or tiles before installation. It can even be installed on any existing hard and uneven floor; no watering or nails are required during installation, and it will Snap together like laminate.

SPC is completely waterproof, so there is no need to worry about its deformation or damage in humid and dark environments. Therefore, it is often used in kitchens, bathrooms, basements and any areas where water leakage or moisture may occur.

SPC flooring has a closed surface due to its dense and non-porous wear-resistant layer, which can effectively prevent most spills from falling on the floor and prevent bacterial growth, so it only needs regular cleaning to keep it tidy.

SPC flooring can imitate the appearance and feel of various wood, stone, porcelain, etc., creating highly realistic visual effects without having to bear the high cost of purchasing wood or stone, etc., and high maintenance costs. SPC flooring allows you to have more design options while ensuring practicality.

SPC flooring greatly improves temperature-related stability. The expansion and/or contraction caused by temperature rise and fall is very small, so there will be no bulges, gaps, etc.

Most brands of SPC flooring have a backing layer, which has a certain thermal/sound insulation effect and can provide a quiet walking experience and good comfort.

The main components of SPC are limestone powder and mixtures, which require only a small amount of PVC components, so they are low in price.

SPC floor installation does not require glue, etc. You only need to use tools to cut and snap them together in the correct order to form a floating floor.

Just sweep or mop regularly.

Wear slippers at home and clean them promptly to avoid damage.

Like other floors, UMeta’s SPC flooring ensures environmental protection and is non-toxic and will not release formaldehyde or any toxic substances. It is an excellent choice for families with children or pets.

UMeta provides wholesale services for SPC Flooring. You can contact us via Email orLivechat.

Package as shown in the following figure.

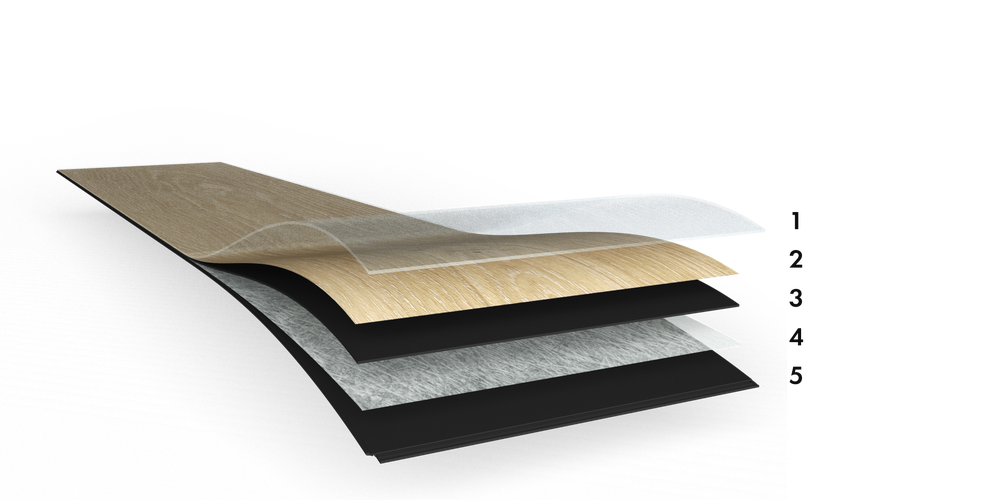

LVT Flooring, the full name is Luxury Vinyl Tile (Advanced Vinyl Tile Flooring), is a new type of flooring material that has attracted much attention in the building decoration materials market in recent years.

UMeta provides wholesale services for LVT Flooring. You can contact us via Email or Livechat.

LVT flooring belongs to semi-rigid sheet plastic flooring, which is a high-end elastic flooring that can realistically imitate wood grain and stone flooring. High elasticity and super strong impact resistance: LVT flooring has a soft texture, so it has good elasticity and can recover well under the impact of heavy objects.

◆ Ultra-light, ultra-thin, fireproof, waterproof, moisture-proof, sound-absorbing, noise-proof and antibacterial properties.

◆ Acid and alkali corrosion resistance

◆ Anti-static and anti-skid

◆ Easy to cut and splice, reduce waste and can be installed quickly

| Model NO. | LVT Flooring/LVT Floor | Material | PVC,Calcium Carbonate |

| Thickness | 4-7mm(4/4.5/5/5.5/6/6.5/7mm) | Density | 0.6-1.0g/cm³ |

| Surface Treatment | Matt/ Parquet | Function | Anti-Slip, Moisture Proof, Rot Proof, Wear-Resistant, Soundproof, Anti-Static |

| Color | Multi-Color | Usage | Household, Outdoor, Commercial |

| Transport Package | Wooden crate | Packaging Specifications | 1226×190mm |

| Certificate | SGS, CE, ISO9001, Dibt | Specification | Regular:1220× 183mm,Specially customizable. |

| WearLayer Thickness | 0.1mm/0.2mm/0.3mm/0.5mm | Production Capacity | 500000pieces /Year |

Products can be customized on demand.

LVT Flooring is installed dry-laying, without the need for glue, and is easy to install and environmentally friendly. The surface of LVT Floor is smooth and flat, and it is very convenient to clean. It only needs to be wiped with clean water without spending too much manpower and material resources.

The materials used in LVT Flooring all comply with national environmental protection standards. The main raw material is luxury vinyl resin, which is natural and environmentally friendly, does not contain harmful substances such as formaldehyde, has no radiation, no toxic volatiles, and is safe and non-toxic.

The material of LVT Floor itself has excellent waterproof and moisture-proof properties. The raw materials have no affinity for anyone. It is suitable for decoration in humid environments and will not become moldy in humid environments. The surface layer of LVT Floors is generally treated with antibacterial treatment to inhibit the growth of bacteria.

The surface of LVT Flooring has a high-tech processed wear-resistant layer using a special UV process. This layer has excellent resistance to scratches, stains and fading caused by sunlight or exposure to chemicals. Depending on the thickness of the wear-resistant layer, the service life ranges from 10 to 50 years. LVT Flooring has good flame retardant properties, will not spontaneously ignite and will not produce toxic substances after burning.

The LVT Floor has elastic recovery capabilities, which disperses foot pressure, makes the feet feel very comfortable, and can elastically recover from the impact of heavy objects.

LVT Floor has good thermal conductivity and heat dissipation performance, and is the first choice for floor heating floor. LVT Floor can make floor heating conduct heat quickly and evenly.

LVT Flooring can replicate the appearance and texture of various natural materials such as hardwood, stone or ceramic tiles. It comes in a wide range of colors and styles. It can even generate three-dimensional scratches on the surface to simulate real wood flooring. It can not only have the desired color, pattern and finish, but also Without the high cost and maintenance requirements of natural materials, they can be customized and flexibly matched to different interior styles and preferences.

| Package Size | 570.00cm * 230.00cm * 245.00cm |

| Package Gross Weight | 1900.000kg |